Managing repair scheme definition

Select the “Manage Repair Scheme Definition” link under the “Maintenance Task” business component.

The “Manage Repair Scheme Definition” page appears.

Note: In the Online Help, task and repair task mean the same and hence have been used interchangeably.

Enter the following fields in the “Search Criteria” group box to retrieve repair tasks.

|

Repair Task # |

The task for which you want to retrieve repair scheme details. (Repair tasks referred to tasks that have repair schemes defined for them.) You can enter the task number in full or specify it partially using the “*” character. The system retrieves those tasks with numbers similar to the number you specify here that hold WBS code with process parameters “WBS Level?”, set as “Root Level” or “Intermediate” and “Allow Sequence Control definition?'”. |

|

Task Description |

The description of the task. You can enter the description in full or specify it partially using the “*” character. The system retrieves those tasks with descriptions similar to that you specify here. |

|

Maint. Object # |

Use the drop-down list box to select the maintenance object. The drop-down list box displays the following: Part # and Aircraft Model #. Specify the number of the part or aircraft in the input box available alongside. You can enter the number in full or specify it partially using the “*” character. The system retrieves those tasks effective for parts/aircraft with numbers similar to that you specify here. |

|

Seq. Control # |

The sequence control # for which you want to retrieve details. You can enter the number in full or specify it partially using the “*” character. The system retrieves all tasks mapped to those sequence controls with numbers similar to that you specify here. |

|

WBS Code |

Use the drop-down list box to select the WBS code of the task. The drop-own list box displays the following: All those WBS codes in Active status defined in the Common Masters component. However, only WBS codes for which process parameters “WBS Level?”, is set as “Root Level” or “Intermediate” and “Allow Sequence Control definition?'” is set as “Yes” are displayed for selection. The system retrieves those tasks with the WBS code that you select here. |

|

Rep. Sch. Op. # |

Use the drop-down list box to select the operator for the repair scheme. The drop-down list box displays those operators that exist in Active status in the Common Masters component. The system retrieves those tasks effective that are effective for the operator you select here. |

|

Task Category |

Use the drop-down list to select the category of the task. The drop-down list box displays those quick codes defined under the quick code category “Task Category” that are in Active status. The system retrieves those tasks in the category that you select here. |

|

Task Type |

Use the drop-down list to select the type of the task. The drop-down list box displays those quick codes defined under the quick code category “Task Type” that are in Active status. The system retrieves those tasks of the type that you select here. |

Click the “Search” pushbutton to display details of repair tasks retrieved by the search function.

The “Primary Task Details” multiline displays the following.

|

Repair Task # |

The task for which you want to create/modify repair scheme. Note a repair task is synonymous with its repair scheme. Click on the data link to create/modify details of the repair scheme. |

|

Task Description |

The short name/description of the repair task. |

|

Rep. Seq # |

The repair sequence number assigned to the repair task in the sequence control. |

|

Part # |

The part for which the repair task is effective. |

|

Rep. Sch. Op. # |

The airline operator for which the repair task is effective. |

|

New? |

Select the ”Create New” link in this column to create a new task and map the task to the sequence control. The data link appears in this column for blank records or if you have retrieved a specific sequence control # through search. Now you can proceed to create a task and automatically map the task to the sequence control. |

|

Child Node |

Select the ”New Child Node” link in this column to create a task, which would be a related task in the repair scheme of the repair task. Note the data link is available only if a repair scheme exists for the repair task. Typically, you use this link to create related tasks and map these to repair schemes. |

|

Edit |

Select the “Edit Task” link in this column to modify information on the task. |

|

Seq. Ctrl. # |

The sequence control # to which the repair task is mapped. Click the data link to modify sequence control for the repair task. However, if the task is not associated with a sequence control, the “Create Seq. control #” link appears here. |

|

Authorization? |

Indicates whether the repair task has been authorized. Displays “Pending”, if the task is in “Fresh” status. Click the data link, if you wish to authorize the repair task. On authorization, the task is automatically mapped to the sequence control #. |

|

W/C # |

The work center where the repair task is executed. |

|

Seq. Ctrl. ? |

Indicates whether sequence control # is essential for the repair task. |

|

Exec. Phase |

The execution phase in which the repair task is executed on the maintenance object. |

|

Mandatory? |

Indicates whether execution of the task on the maintenance object is mandatory. |

|

Child Position # |

The position number of the child part of the part for which the related task that you wish to create is effective. |

|

Child Part # |

The child part of the part for which the repair task is effective. |

|

Child Mfr. Part # |

The manufacturer part number of the child part of the part for which the repair task is effective. |

|

Child Part Mfr. # |

The manufacturer number of the child part of the part for which the repair task is effective. |

|

Prime Part? |

Indicates whether the child part is a prime part. |

|

Repair Process Code |

The repair process code for the task. |

|

Exec. Facility |

The execution facility for the task, such Internal or External. |

|

Repair Agency # |

The repair agency, if the execution facility is “External”. |

|

Std. Disposition |

The type of job performed on the maintenance object. |

|

Repair Classification |

The repair classification of the task. |

|

Base Model # |

The base aircraft model for which the repair task is effective. |

|

A/C Model # |

The aircraft model for which the repair task is effective. |

|

Routing Reqd.? |

Indicates whether shop work order is created automatically or manually for the repair task scheme. |

|

Seq. Modification |

Indicates whether modification of repair sequence in the sequence control is allowed or nor allowed. |

|

Created by & Date |

The employee code of the person who created the record and the date on which the record was created. |

|

Last Modified by & Date |

The employee code of the person who most recently modified the record and the date on which the record was modified. |

Note: If the process parameter “Automatic update of Task-Part effectivity based on Repair Scheme Definition” is set as ‘1’ in the “Define process Entities” activity of the “Common Master” business component, then the system automatically updates the effectivity list of the child Task with the Position Part # and its alternate Part # if they do not exist already.

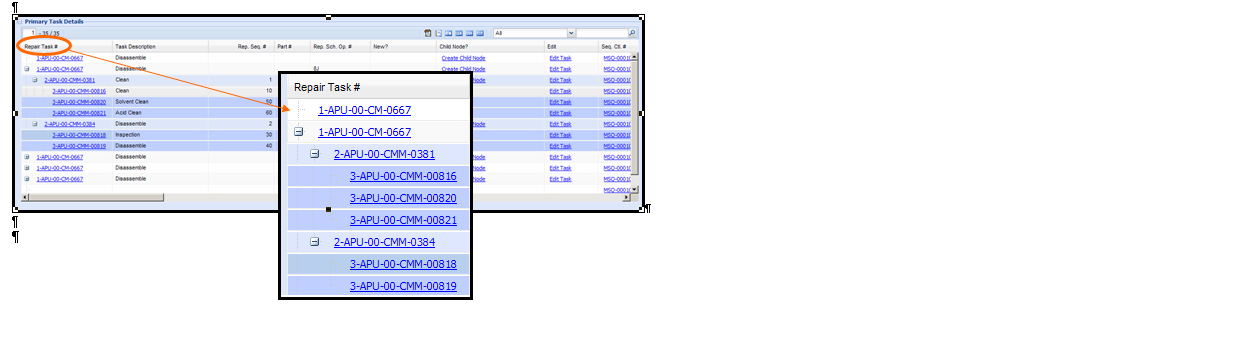

Tree structure in the multiline and its purpose

In the “Primary Task Details” multiline, if a repair scheme is available for the task in the Repair Task # column, data hyperlink appears in the column. You can click the link to access the “Maintain Repair Scheme” page and update its details. Conversely, click the ![]() icon the appearing on the left to display the related tasks in the repair scheme. Each of the following rows displays a related task in the repair scheme. A related task in turn could be associated with a repair scheme, which can be identified by the

icon the appearing on the left to display the related tasks in the repair scheme. Each of the following rows displays a related task in the repair scheme. A related task in turn could be associated with a repair scheme, which can be identified by the ![]() icon. The entire hierarchy of the maintain scheme of the repair task is represented in the multiline using a tree structure as shown in the picture below. The topmost node holds the repair task/root task while the child nodes display the related tasks. A child node may be expanded further to display related tasks and so on. However, if no repair scheme is available for the task, the tree is not displayed in the multiline.

icon. The entire hierarchy of the maintain scheme of the repair task is represented in the multiline using a tree structure as shown in the picture below. The topmost node holds the repair task/root task while the child nodes display the related tasks. A child node may be expanded further to display related tasks and so on. However, if no repair scheme is available for the task, the tree is not displayed in the multiline.